Chengetedza nguva uye chengetedza mari yekurasa yakaderera paunenge uchiita ongororo yehuwandu kana kuchengetedza zvinhu.Yedu silane girazi sampuli mabhodhoro akabatwa nemhepo deposition silane nzira.Surface passivation marapirwo senge silanization uye silicification yakakosha kuchengetedza kutendeseka kwezvimwe zvinhu kana zvakatorwa zvakachengetwa mumidziyo yegirazi.Kugadziriswa kwepamusoro kunogona kuderedza nzvimbo dzinoshanda pane borosilicate girazi pamusoro.

Iyo nzira yekurapa kwepamusoro kwesimbi kana isiri-metallic zvinhu zvine aqueous organosilane sechinhu chikuru.Silanization ine zvinotevera zvakanakira pane zvakajairwa phosphating: hapana inokuvadza heavy metal ions, hapana phosphorus, uye hapana chikonzero chekudziya.Iyo silane yekurapa maitiro haiburitsi sediment, nguva yekurapa ipfupi, uye kutonga kuri nyore.Matanho ekugadzirisa ari mashoma, maitiro ekugadzirisa tafura anogona kusiiwa, uye tangi mvura inogona kushandiswa zvakare.Kunyatsovandudza kusungirirwa kwepende kune substrate.Collinear processing yesimbi sheet, galvanized sheet, aluminium sheet uye mamwe ma substrates.

(1) Silane kurapwa haina simbi inorema inokuvadza senge zingi uye nickel uye zvimwe zvinokuvadza zvinoriumba.Nickel yakaratidzwa kuva inokuvadza kumuviri wemunhu.Sangano reWorld Health Organisation (WHO) rinoti nickel inofanirwa kuburitswa kusvika pazero mushure megore ra2016, ichida kuti nickel haifanirwe kunge iri mumvura ine phosphating wastewater, phosphating vapor uye phosphating grinding dust.

(2) Silane kurapwa inongoburitsa shoma shoma ye silane slag, uye mutengo wekurapa slag wakaderera.

Phosphating slag ishamwari isingadzivisike yechinyakare phosphating reaction.Semuyenzaniso, tambo yekugadzira mota inoshandisa inotonhora inotenderedza mahwendefa inoburitsa inenge 600g yephosphating slag ine 50% hunyoro hwemukati pakugadzirisa 1 mota (inoyerwa ne100m2), uye mutsara wekugadzira wemotokari zana unoburitsa makumi matanhatu ephosphating slag pagore.

(3) Hapana mutsigiri we nitrite anodiwa, nokudaro kudzivirira kukuvadzwa kwenitrite uye zvigadzirwa zvayo zvekuora kumuviri wemunhu.

(4) Kushandiswa kwechigadzirwa kwakaderera, chete 5% ~ 10% yephosphating.

(5) Hapana maitiro akadai sekugadzirisa tafura uye passivation mukurapa silane.Matanho mashoma ekugadzira uye ipfupi yekugadzirisa nguva inobatsira kuvandudza kugona kwekugadzira fekitori, kupfupisa mutsara mutsva wekugadzira, uye kuchengetedza michina yekudyara uye nzvimbo yepasi.

(6) Tembiricha yemumba inogoneka, inochengetedza simba.Silane tank solution haidi kudziyirwa, uye yechinyakare phosphating kazhinji inoda 35 ~ 55 ℃.

(7) Hapana kupokana nemaitiro aripo emidziyo, uye hapana shanduko yemidziyo inogona kutsiviwa zvakananga nephosphating;Iyo inopindirana neyekutanga yekuputira maitiro uye inogona kufananidzwa nemhando dzese dzependi uye hupfu hwehupfu hunoshandiswa.

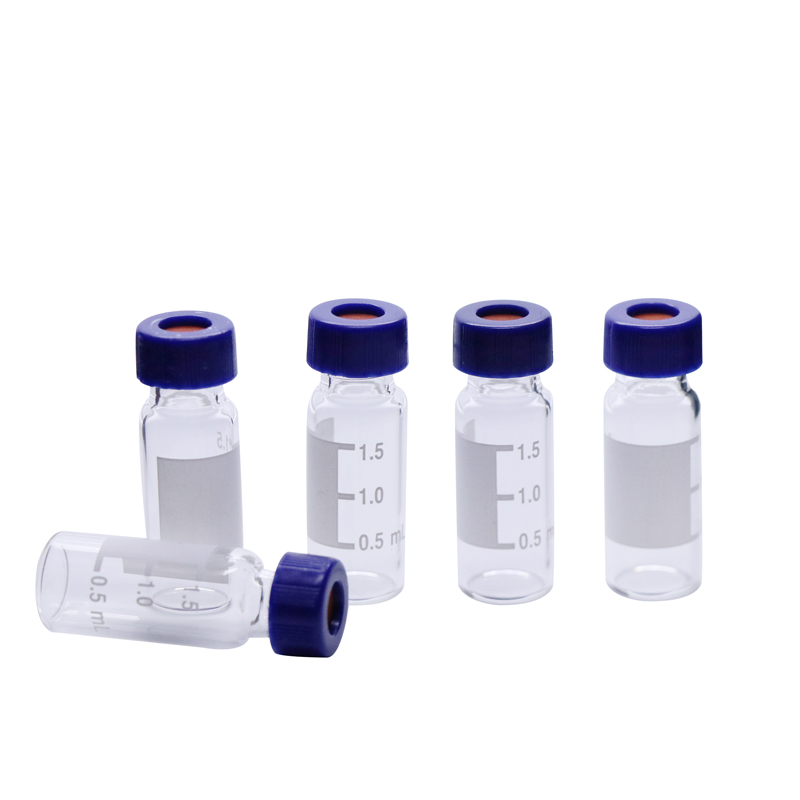

Borosilicate girazi chinhu chakakurumbira cheHPLC mabhodhoro nekuti ine yakanakisa kemikari uye yekupisa inodzivirira zvivakwa.Mhando yegirazi iyi yakanyatsokodzera HPLC maapplication nekuti inokwanisa kushingirira tembiricha yakakwira uye zvinonyungudutsa zvakasimba izvo zvinowanzo shandiswa muHPLC.

Paunenge uchisarudza HPLC mabhodhoro, zvakakosha kufunga nezvemhando yesampuli iri kuongororwa uye mamiriro ayo ongororo ichaitwa.Amber borosilicate girazi HPLC mabhodhoro ane 9mm kuvhurwa isarudzo yakakurumbira kune akawanda marabhoritari maapplication nekuda kweakanakisa maitiro ekuita uye kuenderana neakasiyana masampuli nemamiriro.

Pamusoro peiyo vial pachayo, septa inodiwawo pakuongorora kweHPLC.Iyo septa idiki, denderedzwa chidimbu chechinhu chinokwana mubhodhoro uye chinoshanda sechisimbiso.Inobvumira kuiswa kwemuenzaniso muvharo uye inopawo chipingamupinyi pakati pemuenzaniso uye sirinji yeHPLC, kudzivirira kusvibiswa.Pakusarudza septa yeHPLC vials, zvakakosha kufunga nezvemhando yesampuli iri kuongororwa uye mamiriro ayo kuongororwa kuchaitwa.

Nguva yekutumira: Mar-30-2023